PRODUCT CATEGORY

PRODUCT CATEGORY

CONTACT US

Phone

Email

Address

6 Cuizhu St, Zhong Yuan Qu, Zheng Zhou Shi, He Nan Sheng, China, 450001

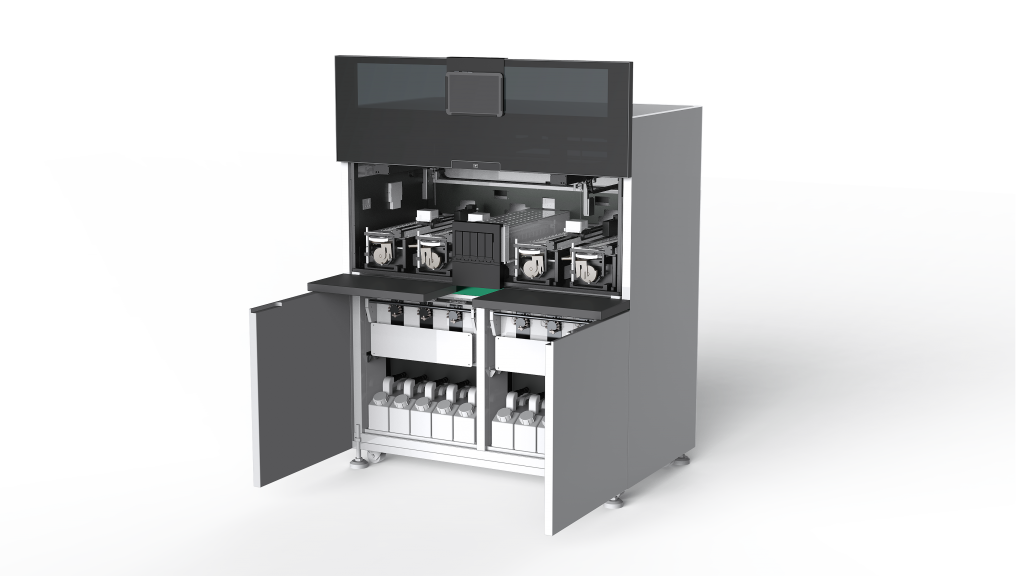

CNT360 Full Automatic IHC&ISH Stainer

Discover seamless efficiency in your IHC & ISH workflow with the CNT 360 full-automatic IHC & ISH stainer. This all-in-one powerhouse excels at executing multiple immuno-staining protocols on a single platform, providing unparalleled fast turnaround time and high-throughput capabilities. Elevate your laboratory's productivity with our ready-to-use reagent kits and protocols, meticulously crafted to guarantee optimal staining results. Trust CNT 360 as your one-stop solution for a comprehensive and streamlined IHC & ISH workflow, ensuring precision, speed, and top-tier staining quality.

Product Features

CNT360 Full-automatic IHC & ISH Stainer Overview Video

Key Features

-

High-throughput

M1: 60 slides per run | M2: 120 slides per run

-

Fast Turnaround Time

2.5 hrs turnaround time, powered by robotic arms and bulk liquid trains.

-

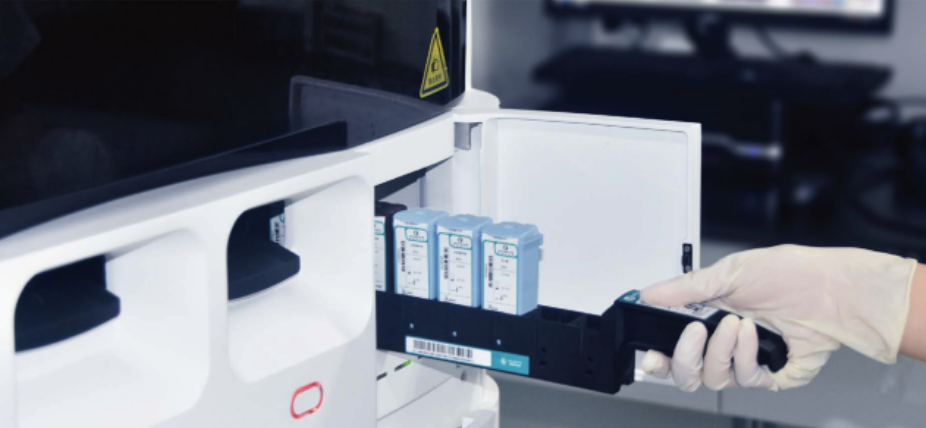

Intuitive Operation

Detachable touch-pads with remote control capability. Customizable protocols and LIS integration.

-

Temperature Control

Constant temperature control for both slide chamber and reagent chamber.

-

Flexibility in Slides and Reagent Placement

Allows loading and unloading of reagent and slides during protocol runs. Supports multiple protocols to run simultaneously.

-

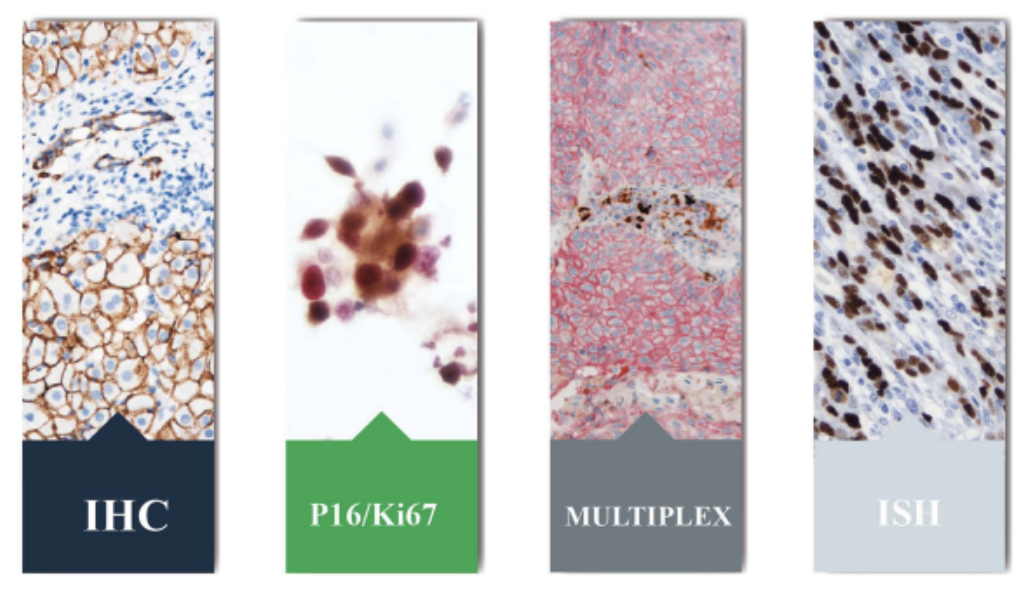

Multifunctional

Supports IHC, ISH, Multiplex IHC, IF and ICC protocols.

Specification

General Characteristics

| Specification | Description |

| Full-automatic: | Baking, deparaffinization, antigen retrieval, blocking, detection, counterstain – for IHC, Multiplex IHC, and ISH applications. |

| Intuitive software interface: | Visual monitoring of reagent volume, running time, and fault messages. |

| Waste Separation: | Non-toxic deparaffinization solution. Separate waste containers for hazardous (DAB) and non-hazardous waste. |

| Slide Capacity: | M1: 4 trays, 60 slides; M2: 8 trays, 120 slides |

| Turnaround Time: | 2.5 hrs |

| Robot design: | M1: 2 main robot arms, 4 bulk liquid trains; M2: 4 main robot arms, 8 bulk liquid trains |

| Temperature control: | Reagent chamber: 14–18°C; Slide chamber: 25–30°C for incubation (slides can be heated up to 100°C for antigen retrieval) |

| Dispense volume: | Adjustable: 100 µL, 120 µL, or 150 µL |

| Reagent container capacity: |

5mL, 10mL,25mL and 40mL |

| Number of reagent container spots: | M1: 70 spots; M2: 140 spots |

| Bulk liquid container: | 4L × 6 |

| Waste containers: | Non-hazardous: 4L × 3; Hazardous: 4L × 1 |

| Fluid probe: | Stainless steel |

Environmental Requirements

| Specification | Description |

| Operating temperature: | 5°C – 35°C (41°F – 95°F) |

| Maximum heating energy output: | 2800 VA |

| Dimensions (L × W × H): | 1370 mm × 820 mm × 1600 mm |

| Weight: | M1: 400 kg; M2: 800 kg |

Electrical Parameters

| Specification | Description |

| Voltage and Mains frequency: | AC 110V/60Hz or AC 220V/50Hz |

| Power consumption: | 2800 VA |

| Document: | ⬇️ Download User Manuel |

Certificate

More Info

MicroStackerTM – The Dedicated Detection System

The innovative MicroStackerTM technology enables orientation-controlled attachment of Fab’ fragments of IgG onto the poly-HRP core using micro-polymer scaffolds.

Its proprietary Fab’ labeling method avoids the occasional blocking of antibody binding sites during the bioconjugation process, enhancing the polymer’s sensitivity.

Biotin-free detection eliminates background staining from endogenous biotin, ensuring precise and reliable results.

![[Instrument] MicroStacker™ Plus Polymer Detection Kit [Instrument] MicroStacker™ Plus Polymer Detection Kit](https://www.celnovte.com/wp-content/uploads/2020/08/3.gif)