PRODUCT CATEGORY

PRODUCT CATEGORY

CONTACT US

Phone

Email

Address

6 Cuizhu St, Zhong Yuan Qu, Zheng Zhou Shi, He Nan Sheng, China, 450001

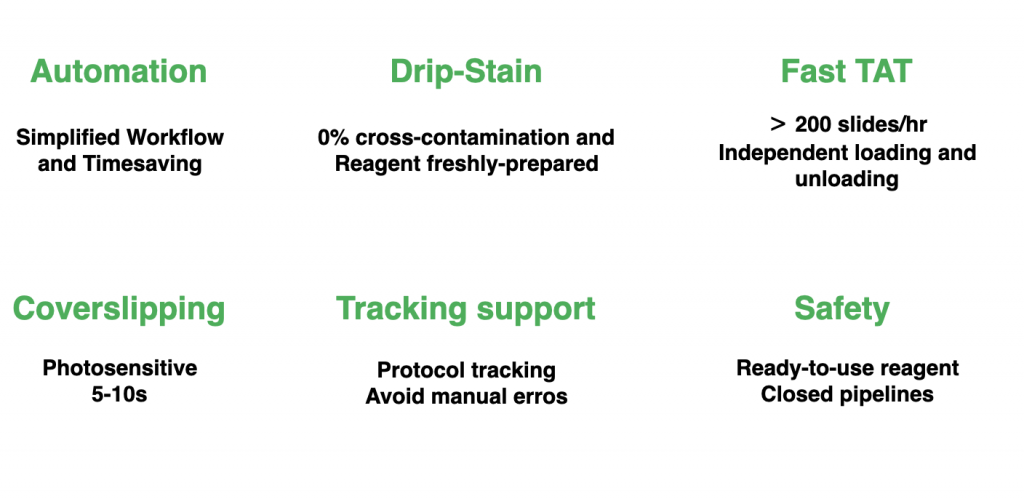

Product Features

Pain Points in the Current H&E Staining Workflow

The current H&E (Hematoxylin and Eosin) staining workflow presents several challenges:

- Exposure to hazardous chemicals: Posing risks to laboratory personnel.

- Standardization challenges: Inconsistent staining outcomes and unreliable results.

- Cross-contamination risks: Manual handling of samples jeopardizes the integrity of experiments.

- Labor-intensive and time-consuming: Manual workflow incurs significant time costs, hindering productivity.

These issues highlight the urgent need for an automated solution that prioritizes safety, consistency, and efficiency in histological staining processes.

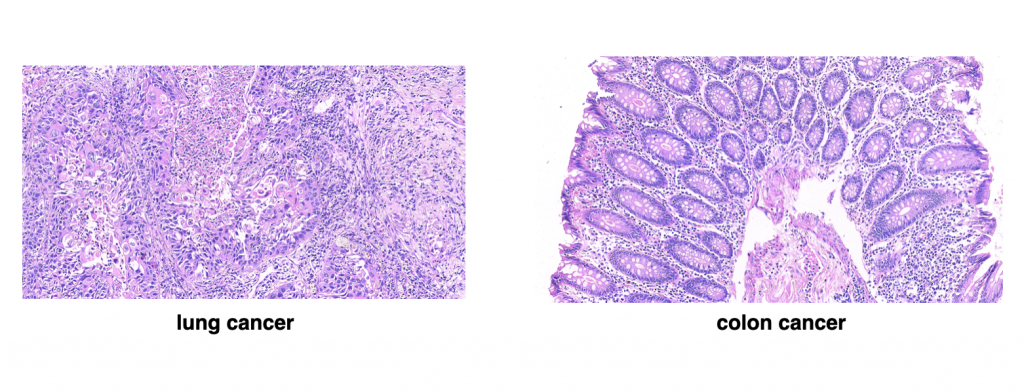

CNT 620 Fully Automatic H&E Drip-Stainer and Coverslipper

The CNT 620 Fully Automatic H&E Drip-Stainer and Coverslipper offers a comprehensive, streamlined solution to address these pain points:

- Zero cross-contamination: Freshly prepared reagents ensure optimal staining quality and eliminate contamination risks.

- High throughput: Capable of processing over 200 slides per hour.

- Flexible operation: Independent loading and unloading to accommodate variable sample volumes seamlessly.

- Sample integrity: Photosensitive design preserves sample quality throughout the process.

- Fast processing times: 5–10 seconds per slide for rapid, efficient staining.

- Protocol tracking: Ensures traceability, minimizes errors, and enhances reproducibility.

- Ready-to-use reagents: Simplify operation and reduce manual preparation steps.

- Closed pipeline system: Ensures complete containment and minimizes exposure to hazardous materials.

The CNT 620 sets a new benchmark for high-throughput, automated H&E staining systems, delivering accuracy, speed, and reliability for modern histopathology labs.