5 Common Staining Problems and How Celnovte Stainers Solve Them

2025-09-26

By admin

Challenges and Opportunities of Staining Technology

In pathology, staining technology acts like a detective’s lens. It serves as a vital step in revealing facts about illness and directing care strategies. Yet, this routine staining task frequently meets various hurdles. These include uneven outcomes, too much background color, lengthy methods, and mistake-prone steps. Such problems not only harm diagnostic precision but can also slow down ideal care for individuals. As a leader in molecular and oncological pathology diagnostics, Celnovte grasps these issues. We focus on supplying fresh, effective, and exact pathology diagnostic answers. This includes our strong stainer lineup. These are built to tackle the five frequent staining hurdles you face each day. They aid labs in reaching more correct and swift diagnoses.

Staining Problem 1: Uneven Staining and Poor Results

Diagnostic Impact: Errors and Delays

Uneven staining ranks as a frequent issue in pathology labs. Varied staining strength or spread across tissue parts can complicate reading the main details. These details involve cell shapes and antigen display. In some cases, this can cause wrong diagnoses. For instance, slight variations in antigen display during immunohistochemistry (IHC) staining can notably affect tumor level, phase, and outlook. This unevenness wastes precious samples and supplies. It also causes repeated tests and extended diagnostic periods.

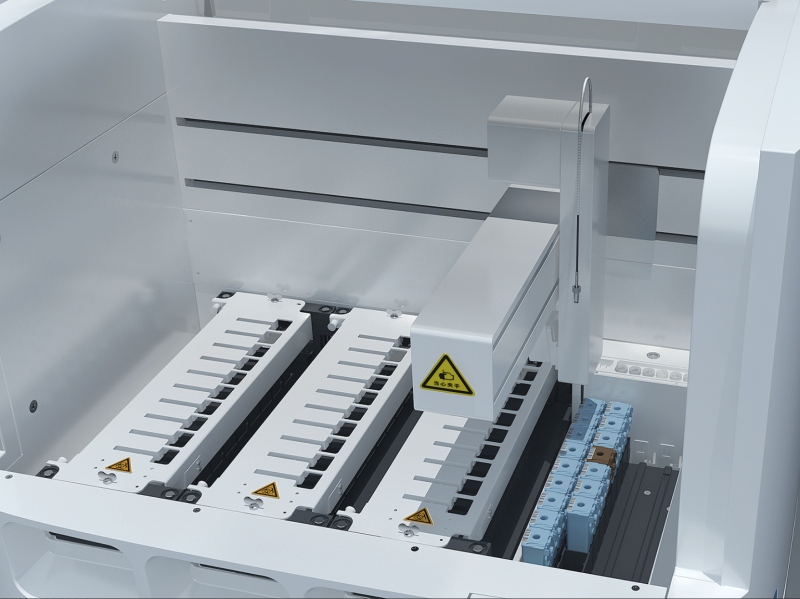

Celnovte Solution: Precision and Uniformity of IHC Stainers

Celnovte’s IHC stainers aim to fix the matter of staining evenness. Our IHC stainers, like the CNT320 Fully Automated IHC Stainer, include modern fluid management setups and exact heat control. They make sure reagent additions, reaction periods, and heats stay firmly managed for each slide. As a result, staining remains steady from the initial slide to the final one. The fully automatic process cuts down human mistakes. It guarantees repeat reliability across groups. This delivers dependable diagnostic outcomes. Whether you operate in a big, busy lab or a minor, CLIA-certified one, Celnovte supplies a small IHC stainer. This balances speed and accuracy.

Staining Problem 2: Excessive Background Staining and High Nonspecificity

Diagnostic Impact: Difficulty in Interpretation and Risk of Misdiagnosis

Too much background staining or nonspecific coloring presents another key hurdle in IHC and immunofluorescence (IF) tests. Too much background can cover faint positive signs from the target antigen. This makes it hard for pathologists to correctly tell apart positive signs from nonspecific links. It greatly disrupts result reading and raises the chance of wrong or overlooked diagnoses. This wastes time on image review. It might also demand expensive repeat tests.

Celnovte Solution: MicroStacker™ Detection System and Optimized Antibodies

Celnovte supplies a fine answer to this issue with its own MicroStacker™ Detection System. Using modern polymerase technology, MicroStacker™ notably boosts target signs. At the same time, it cuts down nonspecific background staining. By tuning supply makeup and reaction speeds, this setup ensures exact linking of the probe to the target antigen. This leads to plain, strong-contrast staining outcomes.

Moreover, Celnovte’s home-made primary antibodies play a vital role in fixing background staining problems. Our own antibodies, including those for ER and HER2, have earned top scores in NordiQC reviews for six straight years. These antibodies have passed strict checks. They hold very high specificity and bond strength. This allows the correct spotting of target antigens. It also notably lowers nonspecific links. Thus, it ensures correct and dependable diagnostics. Paired with the MicroStacker™ setup and fine antibodies, Celnovte’s answers provide unmatched staining clarity.

Staining Problem 3: Long Turnaround Time and Error-Prone Manual Operations

Diagnostic Impact: Inefficiency and Labor Costs

Old pathology staining flows often include many hand-done steps. These are lengthy and depend on the worker’s ability. Hand pipetting, waiting, and cleaning methods are not just slow. They are also open to human mistakes, like wrong supply additions and poorly managed wait times. These mistakes directly harm the staining standard and result in trustworthiness. In busy labs, the narrow spot of handwork stands out more. It limits diagnostic speed and raises running costs.

Celnovte Solution: Automated IHC Stainer, Optimizing Efficiency and Accuracy

Celnovte’s IHC stainers seek to reach a jump in speed through automation. For example, the CNT330 Fully Automated Multiplex IHC Stainer automates the tricky staining process. This covers deparaffinization, antigen retrieval, antibody waiting, counterstaining, and cleaning. It fully removes hand involvement. This automation not only cuts down turnaround time a lot. It also wipes out human mistakes through standard steps. Thus, it ensures high steadiness and repeatability from test to test. By lowering labor costs, labs can put more effort into result review and study. This tunes human resource use and boosts overall speed.

Staining Problem 4: Limited Throughput, Unable to Meet Large-Scale Demand

Diagnostic Impact: Bottlenecks and Scalability Challenges

For big hospitals or pathology hubs, the daily amount of pathology samples handled is huge. Weak throughput of current staining tools ranks as a frequent problem. Limited tool capacity and slow handling speeds often cause sample piles. This delays diagnostic reports. It can even harm the medical service standard. When dealing with growth, labs often face trouble in quickly growing their tools. This forms a narrow spot for expansion.

Celnovte Solution: High-Throughput and Flexible IHC Staining Platform

Celnovte’s IHC stainer lineup gives high-throughput answers to fit the needs of labs of all sizes. We supply a broad range of IHC stainers with adaptable setups. These go from small devices for minor labs to fully automated, high-capacity platforms for busy labs. For instance, the CNT360 Fully Automated IHC & ISH Stainer can handle many slides at once. This effectively raises overall lab throughput. It also shortens diagnostic turnaround times. Besides, we keep building more effective automation answers. These ensure your lab can handle rising sample amounts with ease. They also keep top diagnostic skills.

Staining Problem 5: Special stains are complex and difficult to perform

Diagnostic Impact: Technical Barriers and Unstable Results

Beyond usual H&E and IHC staining, many special stains hold a key role in pathological diagnosis. These aid in spotting fungal, bacterial, and connective tissue illnesses. Yet, special staining steps are often trickier and detailed. They demand high skills from the lab worker. Handwork can easily skip steps or do wrong actions. This leads to unsteady staining outcomes or failure to meet diagnostic needs. Thus, it raises skill barriers.

Celnovte Solution: Professional Special Stainers and Comprehensive Technical Support

To tackle the tricks of special staining, Celnovte supplies expert Special Stainers. Our exactly built special stainers can automate various tricky special staining protocols. This ensures the correctness and repeatability of each staining step. It not only lowers work difficulty and the need for worker know-how. It also notably boosts the win rate and steadiness of special staining outcomes.

Celnovte also gives full skill support. This includes direct training, problem fixing, and staining method tuning tips. These ensure your lab can fully use its tool’s strengths. You can smoothly do various special staining tests. This boosts diagnostic skills.

Partner with Celnovte to Create a New Future in Pathology Diagnosis

With pathology diagnosis growing more detailed and personal, picking high-quality, dependable staining tools and answers is key. Celnovte’s IHC stainers, MicroStacker™ detection systems, fine primary antibodies, and special specialty stainers aim to basically fix your staining hurdles. We focus on boosting diagnostic correctness, speed, and repeat through fresh technologies.

Now marks the moment to update your lab and leave behind dullness and doubt! Contact Celnovte today tel:+1-4012094076 or info@celnovte.com to find out more about our products or set a talk with a pro. Let’s start a fresh part in pathology diagnostics as a team.

FAQ

Q: What certifications does Celnovte hold for its products?

Celnovte’s facilities in China are NMPA & GMP compliant, and certified for ISO13485 and ISO9001. Our products have also received CE mark approval and FDA approval.

Q: How do Celnovte’s primary antibodies ensure high quality?

Celnovte’s self-cloned primary antibodies have consistently achieved optimal results in NordiQC assessments for 6 consecutive years, including for critical markers like ER and HER2, demonstrating their high specificity and reliability.

Q: What proprietary technologies does Celnovte offer?

Celnovte holds proprietary intellectual property for MicroStacker™ and SuperISH™, which are key to our market-leading portfolio of IHC and ISH reagents and instruments.