How Does Celnovte’s CNT330 Stainer Achieve 30-Slide High-Throughput in 3.5 Hours?

By admin

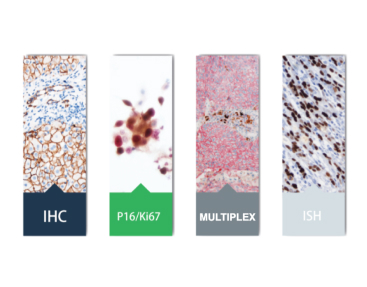

Medical diagnostics is changing fast. Pathology labs must handle more samples quickly, accurately, and efficiently. They need high-throughput capacity to give timely and reliable results. Celnovte, a leader in molecular and tumor pathology diagnostics, has created the CNT330 Full Automatic Multiplex IHC Stainer to meet this need. This system improves lab workflow, making Immunohistochemistry (IHC), In Situ Hybridization (ISH), and Immunocytochemistry (ICC) testing faster and more standardized.

Unlocking High-Throughput Performance

The CNT330 is built for high-throughput staining. It has features that work together to reduce manual work, speed up processing, and handle more slides. This design helps labs keep up with growing demands without sacrificing quality.

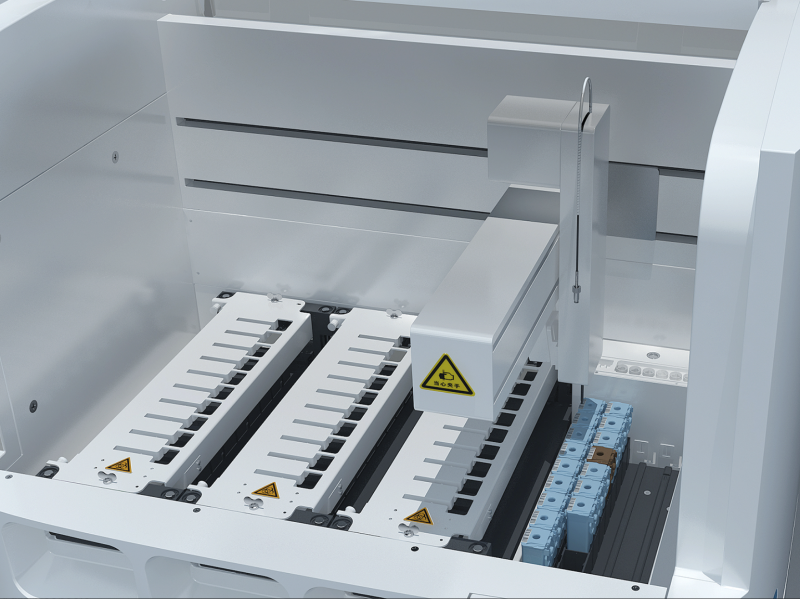

Unmatched Slide Capacity and Continuous Operation

The CNT330 can hold many slides at once. It has three separate trays, each holding 10 slides, for a total of 30. This setup lets labs load and unload slides while the machine is running. Technicians can keep the workflow smooth because of this flexibility. It avoids delays common in batch processing, ensuring a steady output of completed slides.

Complete Automation for Simplified Workflows

The CNT330 automates the entire staining process. It takes care of steps like drying, deparaffinization, antigen retrieval, blocking, detection, and counterstaining for IHC, Multiplex IHC, and ISH. This automation cuts down on manual tasks, which saves time. It also reduces mistakes and keeps results consistent across all slides. Plus, each of the 30 heating units can heat slides to 100ºC. This ensures antigen retrieval works well every time, boosting the system’s efficiency.

Efficient Turnaround Times

For high-volume labs, speed is of the essence. The CNT330 finishes slides in 3.5 hours or less. This kind of turnaround time is critical for labs that need fast results to help with patient care. The device can process many slides at once thanks to automation. That aspect directly contributes to its fast workflow, helping labs meet very tight deadlines.

Precision and Reliability Beyond Manual Processes

Accurate results are equally vital as speed for high-throughput labs. The CNT330 uses real-time monitoring with infrared and camera technology for precise label reading. This reduces the possibility of errors associated with manual handling. It holds every slide to its own protocol, ensuring high quality. The system does away with the need for costly retests without making errors. That saves time and resources in the setting of a busy laboratory.

Advanced Features for Enhanced Efficiency

Aside from its core high-throughput capability, the CNT330 has several advanced features that drive its efficiency, precision, and economical operation.

Economical Reagent Management

Cost-effectiveness is essential in any high-throughput laboratory. The CNT330 is cost-saving to laboratories in terms of reagent consumption with a minimum dispense volume of 100 µL. The 36 reagent container positions, which can accommodate 5 mL, 10 mL, 25 mL, and 40 mL volumes, and bulk liquid containers of 2.5 L, allow the system to have precise control over reagent dispensing to reduce waste.

Superior Detection with MicroStacker™ Technology

For sensitive and specific detection of high-throughput diagnostics, the CNT330 is equipped with Celnovte’s innovative MicroStacker™ polymer technology. The proprietary technology of the company enables orientation-controlled binding of IgG Fab’ fragments to a poly-HRP core via micro-polymer scaffolds. The new Fab’ labeling method does not allow the binding sites of antibodies to be blocked by bioconjugation, enhancing the sensitivity of the polymer. Besides, its biotin-free detection eliminates the background staining of endogenous biotin, delivering precise and reliable results even with difficult samples.

Intuitive User Experience

Despite its advanced functionality, the CNT330 features an easy-to-use interface with graphical prompts displaying reagent volume and program status. The layout simplifies operation, reduces the learning curve for lab personnel, and allows monitoring of runs easily, once again contributing to an error-free and seamless high-throughput workflow.

Flexibility and Customization

The system is engineered for flexibility, with the capacity to accommodate multiple devices controlled from a central computer. This allows for scalable operation to meet throughput needs of various sizes. The CNT330 also features user-programmable protocols and LIS interfacing, enabling labs to set up staining protocols for specific research or clinical applications and integrate the stainer with existing laboratory information systems installed, once again enhancing operational productivity and data management. It also offers waste containers segregated from one another for hazardous (DAB) and non-hazardous waste, reducing disposal costs and environmental impact.

Celnovte’s Commitment to Innovation

Founded in 2010, Celnovte is headquartered in Rockville, MD for reagent and instrument development. It also has subsidiaries in Shenzhen for instrument R&D, in Suzhou for research-use product development, and in Zhengzhou, China for manufacturing. Our facilities in USA and China are NMPA & GMP compliant and are certified for ISO13485, ISO9001, FDA and CE IVDR. Nowadays, Celnovte has established an extensive domestic and international pathological network, reaching over 2300+ top hospitals in China and over 40+ countries worldwide.

Our mission is to elevate precision in cancer diagnostics and enrich patients’ lives through innovative products and services. We aim to be a global leader in delivering top-quality diagnostic services by prioritizing product quality, unmatched customer satisfaction, advancing scientific innovation, and building a premier organization committed to make better, do better, and be better for our customers, employees, partners, and the patient worldwide.

Our Range of Automated Stainers

The CNT330 is part of Celnovte’s extensive range of instruments, which also includes the CNT360 Full Automatic IHC&ISH Stainer, the CNT320 Full Automatic IHC Stainer, and the CNT300 Full Automatic Multiplex IHC Stainer. We also provide specialized detection systems like the MicroStacker™ Flex Polymer Detection Kit and MicroStacker™ Plus Polymer Detection Kit to complement our stainers. Our strength encompasses immunochemistry, histology, molecular, cytology, and digital pathology with clinical solutions, research collaboration, and OEM/ODM partnerships.

Conclusion

The Celnovte CNT330 Full Automatic Multiplex IHC Stainer is a reflection of contemporary high-throughput laboratory automation. By featuring high slide capacity, complete automation, fast processing, accurate features, cost-effective reagent usage, and an easy-to-use interface, the CNT330 enables pathology laboratories to process larger workloads more efficiently and dependably than ever before. Selecting the CNT330 is about revolutionizing your laboratory’s workflow, attaining higher standardization, and providing consistent, accurate, and timely results in today’s high-pressure diagnostic setting.

FAQ

Q: What applications does the CNT330 accommodate?

A: The CNT330 accommodates IHC, ISH, Multiplex IHC, and ICC protocols.

Q: How many slides can the CNT330 process at one time?

A: It can process as many as 30 slides in three independent frames, 10 slides per tray, and continuous loading.

Q: Why is the CNT330 “full automatic”?

A: It automates the processes of baking, deparaffinization, antigen retrieval, blocking, detection, and counterstaining.

Q: What is MicroStacker™ technology?

A: It is a new polymer technology for sensitive and specific detection, by orientation-controlled attachment of Fab’ fragments and offering biotin-free detection to avoid background staining.

RELATED PRODUCTS