Home

Home

Product

Product

HISTOLOGY

HISTOLOGY

HISTOLOGY AUTOMATION

HISTOLOGY AUTOMATION

CNT 520 Fully Automatic Special Stainer and Coverslipper

CNT 520 Fully Automatic Special Stainer and Coverslipper  PRODUCT CATEGORY

PRODUCT CATEGORY

CONTACT US

6 Cuizhu St, Zhong Yuan Qu, Zheng Zhou Shi, He Nan Sheng, China, 450001

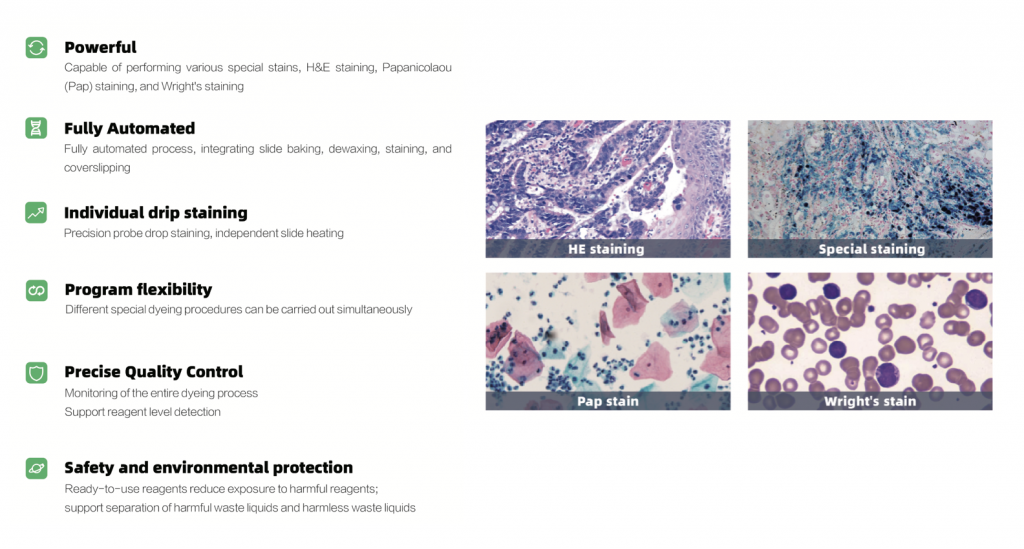

Product Features

Pain Points of the Current Special Stain Workflow

The current special stain workflow presents multiple challenges for pathology and research laboratories. Complex and detailed protocols require meticulous attention and extensive expertise, often leading to errors and inconsistent results. In addition, the stability of reagents is a common concern, as some staining solutions degrade rapidly, compromising staining quality and necessitating frequent replacements.

Exposure to hazardous chemicals also poses significant safety risks to laboratory personnel, requiring strict protective measures and infrastructure investments. Furthermore, the lack of flexibility in traditional dip stain methods limits the ability to run different protocols simultaneously, reducing laboratory productivity and efficiency.

Introducing the CNT 520 Fully Automatic Special Stainer

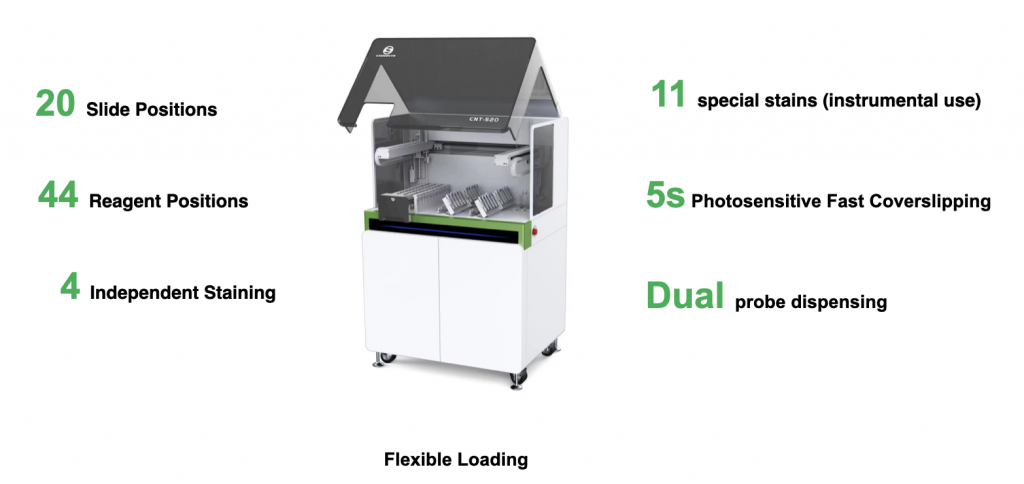

The CNT 520 Fully Automatic Special Stainer and Coverslipper is designed to address these challenges and transform special staining workflows. With 20 slide positions and 44 reagent positions, it seamlessly accommodates diverse samples and complex protocols.

Its key innovation is four independent staining stations, enabling simultaneous processing of multiple protocols without cross-contamination. This enhances laboratory flexibility and throughput. The system also supports 11 special stain protocols, meeting a wide range of diagnostic and research needs.

Automated coverslipping further streamlines laboratory operations, eliminating manual bottlenecks and boosting overall productivity. Engineered for reliability and consistency, the CNT 520 delivers high-quality staining results that empower fast-paced clinical and research environments.

Key Advantages of the CNT 520 Special Stainer

– Efficient workflow: Automated processes save time and minimize human error.

– Independent staining stations: Run multiple protocols simultaneously without cross-contamination.

– Versatile staining options: Supports 11 special stain protocols for broad diagnostic utility.

– Automated coverslipping: Maximizes lab throughput and enhances safety.

– Reliable and consistent results: Ensures reproducibility and accuracy in every run.

Conclusion

The CNT 520 Fully Automatic Special Stainer and Coverslipper sets a new standard for special stain workflows. By combining advanced automation, flexibility, and safety, it meets the needs of modern laboratories, enabling efficient and precise staining processes that support accurate diagnostics and high-impact research.

Specification

More Info

Related Product

PRODUCT CATEGORY

PRODUCT CATEGORY

Chat

Chat

message

message

Quote

Quote