Maximizing the Lifespan of Your Primary Antibodies

By admin

In any busy pathology lab, the primary antibody is the star player. It’s the one reagent that locks onto the exact protein or marker the pathologist needs to see, whether that’s a cancer indicator or evidence of infection. Labs spend a lot of money buying these antibodies and even more time validating them on their own tissue controls. So when someone asks, “How long will this bottle last?” they’re really asking how long it will keep staining cleanly and correctly before the signal fades or the background gets messy.

The real answer depends on two things: how well the antibody was built in the first place and how carefully the lab treats it day to day. Celnovte focuses on both sides of that equation so pathologists can squeeze every possible month of good performance out of each vial.

The Cornerstone of Pathology: Understanding Antibody Lifespan

Shelf-Life vs. Operational Life: Defining Antibody Longevity

The date printed on the box is the shelf-life—how long the unopened vial stays good if you keep it cold and untouched. What matters far more in daily work is operational life: how many clean runs you get once the bottle is opened, aliquoted, and sitting in the fridge door between IHC runs.

Antibodies are delicate proteins. Their shape has to stay just right to grab the target antigen. Anything that knocks that shape out of whack—heat, repeated freezing and thawing, contamination—can turn a great antibody into a weak one long before the printed expiration date.

The Financial and Clinical Cost of Suboptimal Antibody Performance

When an antibody starts giving pale staining or spotty results, the lab pays twice. First, techs rerun slides and burn through another expensive vial sooner than planned. Second, and much worse, a weak or dirty stain can lead to a wrong call on a cancer case. Nobody wants to under-call a Ki-67 or over-call a HER2 because the antibody simply got tired. Keeping antibodies performing at their best is the cheapest and safest thing a lab can do.

Primary Antibody Degradation: The Unseen Threats to Stability

A lot of little things quietly chip away at antibody performance once the vial leaves the manufacturer’s hands.

Intrinsic Instability: Protecting the Antibody’s Structure

Proteins can get clipped by stray enzymes floating around in the bottle, or they can clump together into useless aggregates. Once clumped, fewer working antibodies are left in solution, so the staining gets weaker, and the background often gets noisier. Good manufacturers add stabilizers and special buffers to slow those reactions down as much as possible.

Nothing hurts antibodies faster than temperature swings. Celnovte’s 500+ ready-to-use primary antibodies are happy at 2–8 °C, but leave them on the bench for an hour too long—or let the fridge warm up over a holiday weekend—and the damage starts adding up quickly. Every minute out of the cold shortens the number of good runs you’ll get.

Extrinsic Challenges: Minimizing Handling and Dilution Risks

The smartest move most labs make is aliquoting the stock bottle into small single-use tubes right after it arrives. That way, the main vial never sees another freeze-thaw cycle, which is murder on protein structure. It also keeps tips from different techs from dipping back into the same bottle and dragging in skin bacteria or leftover protease.

Celnovte’s Commitment to Intrinsic Antibody Quality

Celnovte starts the longevity battle at the production stage by making antibodies that are simply tougher from day one.

Engineered for Durability: Celnovte Primary Antibodies

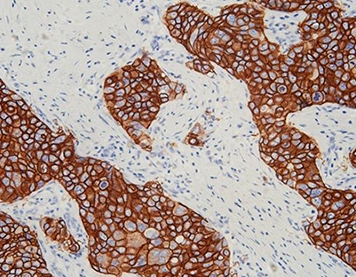

The company now offers over 500 ready-to-use IHC primaries, including their own in-house cloned monoclonal (MMab) and polyclonal (RMab) lines. Popular examples include Ki-67 (C3G4) and HER2 (C1F7). Since 2016, they have rolled out 429 different immunohistochemical primaries, each one put through tight quality checks before it ever ships.

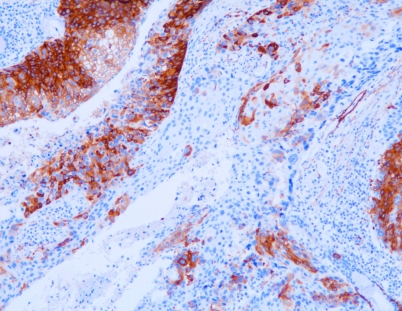

The real proof shows up in independent ring trials. Forty-seven of Celnovte’s self-cloned primaries have earned “optimal” or “good” scores from NordiQC, the tough Nordic external quality program that compares staining side-by-side across dozens of labs. When an antibody scores that well in someone’s lab, you know it will hold its performance in yours for a long time.

Utilizing MicroStacker™ Ultra to Extend Effective Lifespan

Even a top-grade antibody loses a tiny bit of punch after months of daily use. That’s where MicroStacker™ Ultra (launched in 2023) steps in. Its polymer backbone piles on more reporter molecules than older systems, so even if the primary antibody is binding a little less enthusiastically, the final brown or red signal still pops cleanly. Labs report they can keep using the system for a lot of weeks or months longer than they expected because the detection system masks the small drop-off. Background stays quiet while the specific stain stays strong.

Automation: The Master Key to Operational Consistency

Great antibodies and a great detection kit still need gentle, repeatable handling. That’s why automation has become non-negotiable in high-volume labs.

Eliminating Human Variability with Standardized Staining

Hand-staining means one tech might incubate at 37 °C for 29 minutes and another for 32. Those small differences add stress to the antibody molecules and show up as uneven staining across a run. Machines don’t have bad days—they do exactly what they’re told every single time.

The CNT 360 Fully Automatic IHC & ISH Stainer runs entire protocols without anyone touching the slides once they’re loaded.

Key ways it protects antibody life:

-

Precise Incubation – Every slide sees exactly the same time and temperature, no accidental overcooking.

-

Reduced Handling – Diluted working solution stays in sealed lines instead of open troughs where it could pick up contaminants.

-

Workflow Integration – Ready-to-use kits load straight onto the instrument, so there’s no last-minute pipetting errors.

Since 2018, Celnovte has placed more than 800 of these automated stainers in hospitals and reference labs worldwide. That many machines running daily patient cases proves the platform keeps antibodies happy and staining consistent.

The Efficiency Equation: Maximizing Throughput and Minimizing Waste

Automated platforms also use far less diluted antibody per slide—usually just 100–150 µL instead of the 300 µL many techs pour by hand. Less waste per run means the working bottle lasts longer before it’s empty or too old to trust. Add in PolyStacker™ Technology for frozen-section IHC that finishes in as little as 10 minutes, and labs get fast answers without burning through reagent.

Conclusion: Sustaining Diagnostic Quality Through Innovation

How long a primary antibody really lasts comes down to starting with a rock-solid molecule and then treating it right every single day. Celnovte gives labs both pieces: tough, NordiQC-proven primaries (47 scored optimal or good), a forgiving high-sensitivity detection system in MicroStacker™ Ultra that covers small signs of aging, and bulletproof automation on the CNT 360 platform that removes the daily wear and tear of manual work. Put those three together and labs don’t just stretch vials further—they keep turning out clean, trustworthy stains that pathologists can sign out with confidence, case after case.

FAQ

Q: What is the difference between shelf-life and operational life for antibodies?

A: Shelf-life is how long the sealed vial stays good in the fridge. Operational life is how many reliable runs you get once the bottle is opened and in daily use.

Q: How does automation help prolong antibody performance?

A: It locks in exact incubation times and temperatures and cuts down on handling mistakes, so the antibody molecules stay happier longer.

Q: What objective data validate the quality of Celnovte Primary Antibodies?

A: Forty-seven of our in-house cloned antibodies have earned optimal or good marks from NordiQC external assessments.

Q: Can Celnovte’s detection systems make older antibodies still usable?

A: Yes—MicroStacker™ Ultra is sensitive enough to boost even slightly tired primaries and still give strong, clean staining.

RELATED PRODUCTS